Author:

Mike Matthews, Director of Strategic Marketing, Power Integrations, Inc.

Date

02/03/2012

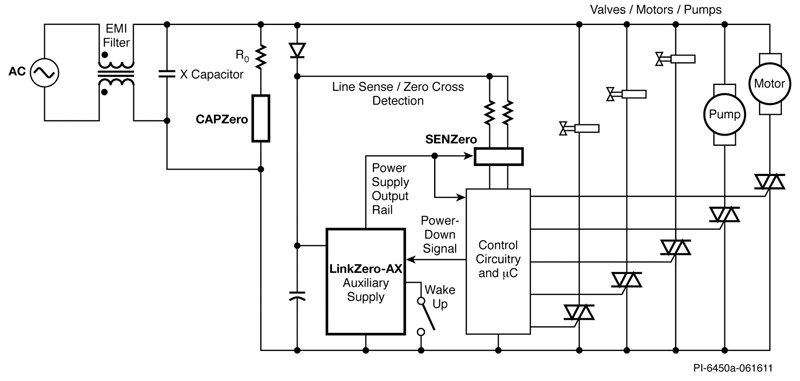

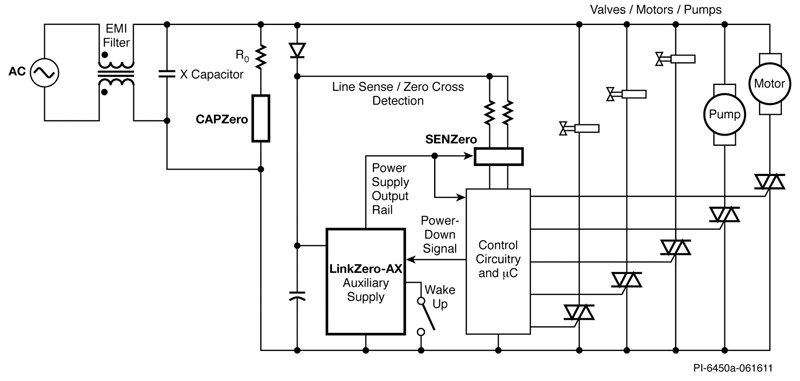

Recent studies have indicated that standby power consumption can range as high as 10 percent of all domestic electricity usage. Over the last few years, multiple programs - including ENERGY STAR, the EU Code of Conduct, and the EcoDesign Directive - have attempted to build awareness about the importance of driving down standby energy loss. Given the growing worldwide focus on power efficiency, it is hardly surprising that white goods manufacturers would like to market their products as offering zero consumption in standby mode. But defining exactly what zero standby means has been a challenge. In any design, there is always some leakage current present. So the question facing designers has been at what threshold is the standby current level considered equivalent to zero? Over the past few years, a growing consensus has emerged for defining zero standby current around specifications set out in IEC 63201. Developed as a guideline for power test procedures, the IEC standard's Section 4.5 specifies a measurement resolution of 0.01 W (10 mW). Accordingly, any measurement <5 mW must be rounded to 0.00 W. While this specification has been widely accepted by cell phone and other battery-powered systems manufacturers, developers of larger systems such as white goods generally cannot reach such low current levels. In turn, they have adopted standards one decimal place to the left. Therefore, any standby current in a washing machine (for example) of <50 mW or 0.0 W is now considered equivalent to zero. New Functionality Users have always been able to achieve zero standby by simply unplugging their system from the AC supply when not in use. But relying on the user to perform this task is unrealistic. Manufacturers would prefer to develop solutions that achieve the same result without inconveniencing the user or compromising system functionality. To accomplish this goal, designers will need to incorporate new functionality into their systems. Household appliances such as clothes dryers, washing machines and coffee makers typically require some input or action on the part of the user to awaken the system from a standby state. Some early zero standby solutions have been implemented using relays and manual switches, but these approaches have typically been too bulky and costly to warrant widespread implementation. To simplify implementation of this function and minimize standby consumption even when the input voltage is still connected, power management IC manufacturers have recently begun offering integrated offline switching ICs that allow designers to achieve 0.00 W standby energy consumption. One example of this type of device, Power Integrations' LinkZero™?-AX (Figure 1), features an innovative power-down mode that turns off the auxiliary supply, including switch-mode operations and internal switch control circuits, when an application is idle. The LinkZero-AX device is sent into power-down (PD) mode by pulling the Feedback (FB) pin high for at least 2.5 ms. Typically generated at the end of a task, such as a washing cycle in a washing machine, this so-called "suicide signal" is sent by the system microcontroller to the offline switching IC telling it to turn off its source of power. Once sent into PD mode, this offline switching IC consumes <4 mW. In this condition, the chip appears inactive, but maintains a voltage on the Bypass / Multifunction (BP/M) pin by drawing very small amounts of current through an internal regulator circuit connected between the Drain (D) and the BP/M pins. This current allows the chip to remain active and await a wake-up signal instructing it to turn the auxiliary power supply back on. The wake-up signal is typically applied via a mechanical push-to-make or capacitively-coupled switch. Once the signal is received, the IC immediately powers up the system microcontroller and the appliance is ready to operate.

While in PD mode, this device also offers an alternative power source capable of delivering up to 500 μA at 4 V from the regulated BP/M pin. This power can be used to manage a wake-up sensor while in PD mode when the rest of the system is in standby, such as powering IR or motion sensors in TV/security systems. While this functionality increases system standby power consumption, it supplies a simple way to power a low-current sensor without requiring the power supply to switch. EMI-Related Challenges Most domestic appliances that feature offline switching power electronics have high voltage and high-current switching waveforms that generate EMI. To reduce the adverse impact of EMI on other systems and meet noise standards, designers insert a filter stage at the AC input. Given their location and the potential to shock the consumer unplugging the appliance, designers typically select safety agency-recognized X-class capacitors. To meet international safety regulations, X-capacitors with values above 100 nF must be discharged automatically with a time constant of less than 1 second when the AC source is disconnected. This function is controlled by one or more discharge resistors placed across the capacitor which normally continue to discharge power from the AC source even when the appliance is in standby mode. Unfortunately, this power loss has become an increasingly large portion of the overall power budget. One way to control this discharge is to add a two-terminal IC which reduces the flow of current through the discharge resistor when the AC source is still connected, but allows the full discharge current to flow through the resistor when the AC source is disconnected. IC manufacturers now offer devices, such as Power Integrations' CAPZero™?, featuring two bidirectional internal switches which are rated to operate with up to 1000 V in either polarity. An internal control function manages the bidirectional switches to hold them off while the AC is connected. When a loss of AC input is detected for longer than 22 ms, both internal switches are turned on to enable discharge of the external X-capacitor in either polarity. Since the device generates its own internal supply and requires no external components, it can be easily inserted into an existing system by simply modifying the circuit board layout around the X-capacitor discharge resistors. Managing Resistor Chains Many white goods products feature multiple resistors going between high-voltage rails and down to a controller. Information is derived from the high-voltage bus or the AC via a signal that is dropped through a resistor/divider to a controller. To better manage power on these circuits, IC manufacturers now offer sense resistor disconnect ICs which integrate multiple 650 V low-leakage MOSFETs designed to be connected in series with resistor chains coupled to high-voltage input rails. With this device, the system can reduce power consumption in standby mode by disconnecting high-voltage sense resistors or resistor dividers connected to the DC high-voltage rail in power factor correction (PFC) or power conversion stages of a power supply. This allows functional blocks within the power supply to be shut down or disabled so they do not draw power when the PSU is not in full operation mode. Leakage current from each MOSFET in the device when in the off condition is less than 0.5 mW from a rectified 230 VAC input rail. Figure 2 shows a schematic of a domestic appliance using all three types of power ICs previously mentioned. Conclusion As the cost of energy continues to rise, standby energy loss will become an increasingly important differentiator for white goods manufacturers. Recent advances in power management ICs offer these companies an ideal opportunity to drive down their products' energy losses to the lowest possible levels. www.powerint.com

While in PD mode, this device also offers an alternative power source capable of delivering up to 500 μA at 4 V from the regulated BP/M pin. This power can be used to manage a wake-up sensor while in PD mode when the rest of the system is in standby, such as powering IR or motion sensors in TV/security systems. While this functionality increases system standby power consumption, it supplies a simple way to power a low-current sensor without requiring the power supply to switch. EMI-Related Challenges Most domestic appliances that feature offline switching power electronics have high voltage and high-current switching waveforms that generate EMI. To reduce the adverse impact of EMI on other systems and meet noise standards, designers insert a filter stage at the AC input. Given their location and the potential to shock the consumer unplugging the appliance, designers typically select safety agency-recognized X-class capacitors. To meet international safety regulations, X-capacitors with values above 100 nF must be discharged automatically with a time constant of less than 1 second when the AC source is disconnected. This function is controlled by one or more discharge resistors placed across the capacitor which normally continue to discharge power from the AC source even when the appliance is in standby mode. Unfortunately, this power loss has become an increasingly large portion of the overall power budget. One way to control this discharge is to add a two-terminal IC which reduces the flow of current through the discharge resistor when the AC source is still connected, but allows the full discharge current to flow through the resistor when the AC source is disconnected. IC manufacturers now offer devices, such as Power Integrations' CAPZero™?, featuring two bidirectional internal switches which are rated to operate with up to 1000 V in either polarity. An internal control function manages the bidirectional switches to hold them off while the AC is connected. When a loss of AC input is detected for longer than 22 ms, both internal switches are turned on to enable discharge of the external X-capacitor in either polarity. Since the device generates its own internal supply and requires no external components, it can be easily inserted into an existing system by simply modifying the circuit board layout around the X-capacitor discharge resistors. Managing Resistor Chains Many white goods products feature multiple resistors going between high-voltage rails and down to a controller. Information is derived from the high-voltage bus or the AC via a signal that is dropped through a resistor/divider to a controller. To better manage power on these circuits, IC manufacturers now offer sense resistor disconnect ICs which integrate multiple 650 V low-leakage MOSFETs designed to be connected in series with resistor chains coupled to high-voltage input rails. With this device, the system can reduce power consumption in standby mode by disconnecting high-voltage sense resistors or resistor dividers connected to the DC high-voltage rail in power factor correction (PFC) or power conversion stages of a power supply. This allows functional blocks within the power supply to be shut down or disabled so they do not draw power when the PSU is not in full operation mode. Leakage current from each MOSFET in the device when in the off condition is less than 0.5 mW from a rectified 230 VAC input rail. Figure 2 shows a schematic of a domestic appliance using all three types of power ICs previously mentioned. Conclusion As the cost of energy continues to rise, standby energy loss will become an increasingly important differentiator for white goods manufacturers. Recent advances in power management ICs offer these companies an ideal opportunity to drive down their products' energy losses to the lowest possible levels. www.powerint.com