Author:

Alfred Hesener Marketing Director - Europe Fairchild Semiconductor

Date

01/07/2012

With 7 billion human beings living on this planet, and at the same time, the energy consumed by human beings is shifting more and more from oil to electricity Improving power density and efficiency in power electronics subsystems It comes as no surprise that power electronics subsystems play a significant role in many applications, and determine their main features to a large extent. They are at the heart of energy production, distribution, and conversion. At every conversion step, some of that precious energy is lost in the process, hence the first main requirement for power electronics is the reduction of losses, or the improvement of efficiency. With the widespread use of electronic power control in more and more applications, the number of power subsystems is also dramatically increasing. For example, new regulations for industrial drives prescribe the use of efficient BLDC motors, requiring electronic control. The second main requirement is therefore increased power density, or reduced size for the power electronics subsystem. With many more electronic power subsystems connected to the grid, most of them operating at high switching frequencies, the noise coupled back into the grid is ever-increasing, despite severe EMI regulations the applications have to comply with. It is therefore advantageous to develop power subsystems that produce less EMI to begin with, e.g. through fast switching with little voltage or current peaks, which is the third requirement. And the fourth requirement is the need for these applications to have high reliability and robustness, especially in the case of applications like renewable energy conversion, where e.g. in the case of an offshore windmill, the power electronics subsystem may not easily be accessed for maintenance and repairs. Renewable energy consumption offers interesting questions for all the four requirements mentioned above. For solar inverters, much of the race for better efficiency has been completed, with most companies offering inverters with 98% or better peak efficiency. Light load efficiency is still lower, and further reductions can substantially reduce heatsink size and weight, so it is not over. However, the development is now also focused on reducing size and cost, while adapting to the newly developing markets like the BRIC countries, while maintaining the robustness and reliability capabilities achieved so far. But where the PV inverters exist in a wide variety of output power, from 2kVA to 1000kVA e.g. for string inverters, the power range for wind power generators is much more limited, and really focusing on the higher power range, currently up to 6MVA per turbine, and increasing. At the same time, significant technical evolution is driving this application: With more and more offshore installations, the average power is increasing, as the rotors can be made larger and the average wind speed is higher. And in order to reduce the weight and cost of the turbine housing, efforts are underway to remove the mechanical gearbox that is needed to maintain constant rotational speed of the turbine, and replacing it with a boost converter / inverter system that will produce constant output voltage and frequency, and can more easily comply with reactive power guidelines. And with larger wind power installations being connected to the mainland grid via a HVDC link, generators with regulated output voltage can simplify the installation and configuration of this offshore subsystem.

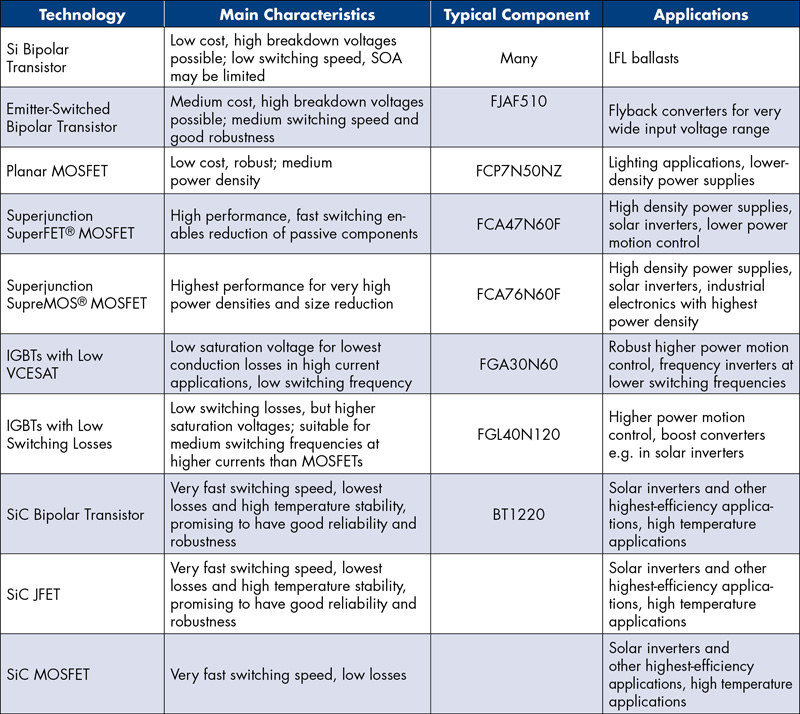

Many power switch technologies co-exist Power electronics subsystems like inverters, boost converters or power conversion stages today almost exclusively come in the shape of a switched-mode power conversion topology. Designers of power electronics applications never had such a wide choice of different and competing technologies for power switches in their applications, ranging from older silicon bipolar transistors, junction and planar (MOS)FET devices to more modern superjunction MOSFETs, IGBTs that exist in many different versions, up to the recent developments using wide bandgap semiconductors such as silicon-carbide ("SiC") or gallium-nitride ("GaN"). But which device is suitable for which applications, what are the advantages and drawbacks? Below table gives a first overview of the different device types, considering commercially available technologies for power conversion applications at higher breakdown voltages above 600V.

The silicon bipolar transistor has been around for a long time, used e.g. as deflection transistor in CRT television sets, with breakdown voltages up to 1500V. It is a well-known device that exhibits good robustness but rather slow switching speeds. The fact that it requires a base current to stay on has some impact on the gate driver design. It has recently become more interesting in cascade circuits, using a low voltage MOSFET as the lower transistor to improve switching speed and benefit from the high breakdown voltage at the same time. One of the most widely used power switch technologies are power MOSFETs. They combine fast switching speeds with high robustness and a built-in body diode with relatively easy gate drive control. Over time, the older planar designs have been succeeded by superjunction devices such as SuperFETÃÃî MOSFETs or SupreMOSÃÃî MOSFETs from Fairchild Semiconductor, resulting in significant reductions in on-state resistance and switching losses. MOSFETs are the preferred device for all applications operating at higher switching frequencies above 20kHz, and for voltages up to 1000V. The other widely used power switch is the IGBT, the combination of a bipolar transistor with a MOSFET to control its base. This device offers much easier control, similar to MOSFETs, with the robustness and high voltage capability of bipolar transistors. Different optimization points for low saturation voltage or low switching losses lead to proliferation of IGBT technologies for different applications. IGBTs are the device of choice for applications at high voltages above 1000V, and for lower switching frequencies and high currents, since the conduction losses do not increase linearly with current as in a MOSFET. Silicon carbide as new base material for semiconductors has been around for a while, in the form of Schottky diodes for high voltages as well as for blue LEDs. The explosive growth of the usage of white LEDs for general lighting applications (which are blue LEDs with a phosphor layer on top) has helped to significantly improve the substrate quality of SiC wafers and the unit process steps necessary for handling this material in a factory. Today's material is much better, and with the resulting increase in wafer diameter, the device cost of these new switches is approaching the necessary cost point for widespread use in industrial applications, taking into consideration the reduction in system cost they allow elsewhere. But, different SiC device concepts are emerging, like bipolar transistors, JFETs or MOSFETs, and they all have their distinct advantages and disadvantages.

The first power switches in SiC were JFETs that use pn-junctions to control the width of the conducting channel inside the device. They are commercially available today from various vendors, and two main categories exist: Normally-on and normally-off devices. With the first, the threshold voltage of the FET has a negative value, so that at VGS=0V the device actually is conducting current. This requires a strong negative voltage to turn the device off, in some cases up to -30V. These devices will exhibit very fast switching and low losses, but the gate drive circuit can be quite complex. A typical use of these devices is in a cascade circuit, in combination with a low-voltage MOSFET. This increases complexity but allows very fast switching combined with easy gate control. Normally-off JFETS are modified so that their threshold voltage is positive. This keeps most of the advantages of SiC JFETs but makes the gate drive circuit a little easier. Still, a negative voltage is required to turn the device quickly and securely off, and to fully turn it on the gate-channel junction may have to be driven positively, in which case a DC gate current needs to be provided by the driver. Both devices have a similar increase in R(DS)ON with temperature compared to Silicon MOSFETs, with the normally-on device showing lower R(DS)ON values in comparison, and the normally-off device degrading more quickly at higher temperatures. For a long time, it was difficult to create stable gate oxides on SiC base material, but these problems appear to be solved now and SiC MOSFETs are commercially available. These devices have a positive threshold voltage in the range of 2V, comparable to silicon MOSFETs, but the manufacturer recommends to drive them with a voltage swing of +20V to -2...5V, whereas silicon MOSFETs generally operate with a gate voltage swing of 0V...12V. The SiC MOSFET only shows a weak increase in RDSON with temperature. Still, high temperature operation is difficult with a SiC MOSFET as it can degrade quickly. A very promising device in SiC is the bipolar transistor. It shows very fast switching, on a par with the other devices, easy high temperature operation, and a good robustness and ease of manufacturing. At the same time, it is very efficient in the usage of substrate surface and has the lowest conduction losses of all these devices, allowing very good performance at moderate chip sizes as compared to the other three devices. But, it will require a DC current to turn on and remain turned-on, so the gate driver needs to be designed accordingly. When the gate driver fails and can no longer provide base current, the bipolar transistor will turn off, providing added fail-safe security. The required base current is a function of the current gain of the device, and the collector current. Using proportional drive, the base current can be reduced at light load, improving the losses and achieving a more uniform efficiency across the entire load range. Also, since for the same reason the SiC bipolar transistor will turn into a current source at roughly twice the load current, it will limit the current in the system in case of a short circuit, potentially avoiding catastrophic failure. All four devices share an interesting characteristic, they exhibit no or very little tail current at turn-off. This is the main reason that enables high switching frequency operation, and is a strong helper to reduce EMI. On the other hand, the tail current in a silicon IGBT can help to damp parasitic oscillations in the system that may exist due to parasitic passive components or layout, so in order to exploit the big advantage of SiC switches, careful layout with minimal stray inductances is required, to avoid voltage peaks. Just appearing on the horizon are new HV switches in Gallium-Nitride (GaN). First prototypes are available, and these devices already offer interesting performance levels. But their manufacturing process can be expensive, both because some GaN devices are produced on a SiC or Sapphire base wafer, and because the process of growing GaN on various substrates is complex and slow. Also, the device processing requires metal and gate systems similar to other 3-5 devices that are not as low cost as conventional silicon processes. Technological research is ongoing to produce these devices on cheaper substrates like silicon, and some companies have announced product availability. And, as they are lateral devices (meaning the current flows horizontally, parallel to the surface of the die, with both drain and source connections on the top of the device), there can be area wasted for bonding pads and current density limitations due to metal stripe current density. Increasing die size for a given R(DS)ON. Lastly, there are still a few unsolved topics regarding ruggedness and reliability of these new devices that will require more research. Robustness and reliability are not the same All the applications targeted for these power switches, and in particular renewable energies, require high robustness and reliability. These two terms certainly do not mean the same, but are often misused. Robustness really is the capability of the device to survive abnormal system states, like high peak voltages, currents or temperatures that are not part of the "usual" system operation, without failure. Reliability means that the device, when operated within datasheet limitations, does not drift or otherwise degrade in performance. Robustness is important, since the power grid is more and more becoming a challenging place to operate in. With large load variations causing strong voltage variation and spikes, more and more decentralized power generation, short circuits, and the new guidelines to provide reactive power in case of too high voltage or frequency, the capabilities of the power devices to absorb energy in case of faults is more and more demanded. And in industrial applications, reliability has always been an important factor for the power subsystem, especially e.g. in the case of offshore wind power generation, where it is difficult and even sometimes impossible to replace a faulty power subsystem in bad weather. Large wind turbines do adjust power output through rotation of the blades, meaning there are three servo drives with inverter inside the rotor to perform this function. They are subjected to large mechanical stresses, vibration and challenging environmental conditions, yet their faultless operation is absolutely critical for the rotor to not being destroyed in very strong wind conditions, at which points the blades have to be adjusted for minimum wind resistance. Similar requirements exist for the servo drive used to position the rotor into the wind, again with potentially catastrophic consequences should this drive fail. Conclusion At this point, design engineers are at a crossroads, one road leading away from well-known silicon switches with very good and well-characterised robustness and reliability, and one heading toward new power switch technologies - such as the Bipolar SiC transistors from Fairchild Semiconductor - that offer superior performance but are not yet field-tested to a large extent. Some insight into the device physics, beyond the manufacturers' claims, is required to make a well-founded decision for industrial applications that are more and more approaching mission-critical requirements. www.fairchildsemi.com