Author:

Helmut Dönges, Dipl -Ing., MBA, Sales Director, Inductive Components, Magnetec GmbH, Germany

Date

09/01/2010

Every day we can read and see on news statements like: "A series of agreements to collaborate on four smart grid projects signed.", "International Smart Grid Action Network launched.", "Beyond the hype: making smart grids happen", "Building a smarter Electric grid.", but what are the real needs? Many countries all over the world are looking forward to replace, extend or modernize their grid infrastructure. In many cases, this is going along with new and intelligent smart metering devices to make smart grids overall reliable and efficient. Current Transformers made -of nanocrystalline soft magnetic materials, provided by MAGNETEC GMBH are providing the ideal transducer principle.

The increasing demand for smart meters in new, modern smart grids requires highly qualified and reliable current transducer technologies. The main question is, whether or not the current transducers are able to meet all requirements from the consumer side, from the energy supplier side and the metrology?

Although all technologies used in smart metering are susceptible to magnetic influence to some degree, the superior performance of current transformers should be considered carefully from the very beginning of any smart meter design. Without the use of current transformer technology, strong magnetic fields can cause distortion in billable counting. In recent times a huge increase in manipulation attempts has been observed worldwide whether in developing regions or highly-industrialized countries. The reason almost certainly is to reduce the apparent energy consumption for lower billing. Here the utilities have to detect revenue losses and continue billing accurately when tampering of energy metering equipment has occurred. Therefore, in general, many transducer principles in electronic meter devices show sensitivity to external magnetic fields when tampering attempts occur. These do not always necessarily need be produced with malicious intention, they can also occur from a stray field of electrical equipment or lines in the vicinity of the meter. To understand and to evaluate the influence external magnetic fields, a series of experiments should be made during the evaluation process and during the field tests of the energy meter. In the case of the influence of an alternating field with an electromagnet (e.g. 50 Hz transformer with I - Core), the sensitive input circuits of the meter with a shunt and with a Rogowski coil can be influenced very strongly. As an example, because of the absence of a magnetic core, the Rogowski coil is immune to magnetic interference caused by external permanent magnets. There is no need to shield the coil by a steel housing as is used for other technologies. On the other hand, the Rogowski coil is extremely sensitive to the external alternating fields mentioned above and has to be magnetically disconnected from its environment. For this purpose a magnetic shielding using a highly permeable material is needed and this needs to be very efficient at any time - even at low field intensities.

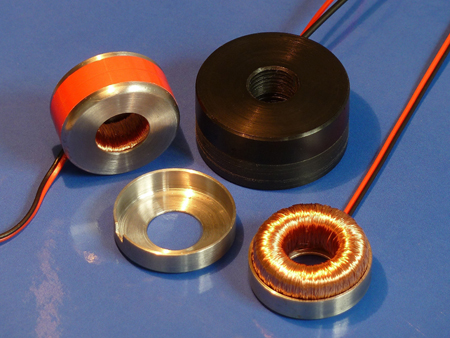

The possibility to influence a current transformer is much lower because of the closed loop principle of the magnetic circuitry. Measurements with an external alternating field do not show significant effects. This application advantage is based on the rotational symmetry of the CT (magnetic core and the winding). Figure 2 shows the virtual field lines of the primary current (green line) and the field lines of an external stray field (red) in the current transformer with a toroidal magnetic core. The primary current induces via the field lines a voltage into the secondary winding, which is available at the terminals. Generally speaking, it seems to be that for all the different measurement principles used in smart electronic energy meters, metallic shields are needed to make any attempts at tampering ineffective. In any case, it can be demonstrated that the current transformer with suitable screening and placement within the meter design can, in economic terms, be designed to be largely insensitive to both types of magnetic fields. Figure 3 shows two types with such an integrated shielding.

The development and understanding of current transformers in electronic energy metering applications needs more than just a simple testing of different transducer solutions. This must be taken into consideration in the development of meters from the beginning to avoid later adjustments in a finalized design of the meter. It could be too late. More and more meter manufacturers and customers are embarking on the development of smart meters for use in a modern smart grid. Current transformer-based technology differs greatly from the many other offerings in transducer technology that exist in this application field where, except for standard functions, they offer no real advantage. In the long run, they usually disappear from the market because they are simply not suitable for future demands and requirements within a modern power grid system. Table 1 shows a broad overview of different measuring principles under specific testing parameters.

The smart grid will, in the future, replace the old grid infrastructure. The requirements for this new generation of smart grid are increased significantly and require high-precision and safe measurement technology and in line with reliable components. Current transformers from MAGNETEC offer a combination of desirable properties from a technical and commercial perspective. The new combination of the current transformer with integrated shielding presents an excellent new opportunity to supply complete high-quality solutions to the global market for electronic energy meters. The new current transformer series, especially for 60A and 100A metering devices in particular can now compete on a cost basis with all widespread transducer systems such as Hall-effect transformers, Rogowski systems or shunts.

For over 25 years MAGNETEC GmbH has developed, produced and marketed high performance soft magnetic core products for many applications within electrical installation technology and industrial automation. The company has developed soft magnetic cores for current transformers, based on nanocrystalline alloys, over a number of years. Additionally, MAGNETEC is pursuing new technologies and applications in the renewable energy sector (photovoltaic and wind energy) and specializing in inductive components for EMC applications. For further information, visit: www.magnetec.de