Author:

Keith Szolusha, LED Drivers Applications Manager, Analog Devices Inc.

Date

02/16/2018

Automobile LED headlight clusters combine high and low beams, daytime running lights, and sometimes signal and clearance lights into a single headlight cluster. The components of the cluster can have vastly different driver requirements, including voltage and current requirements, topologies, power levels or unique dimming functions. Meeting the range of requirements usually means employing separate driver solutions. Using multiple drivers not only complicates BOMs and production; it can make it difficult to meet EMI standards. Each additional driver adds its high frequency signals to the EMI mix, complicating EMI qualification, troubleshooting and mitigation.

Although the headlight cluster for each automobile make and model may be outfitted with a creative variety of LED currents and voltages, they commonly top out at 30W total. With that in mind, there should be a number of drivers that satisfy the power and feature requirements of every string in the cluster. There are not. Such a driver needs to take the relatively wide battery voltage range, and using a buck-boost topology, convert to the wide variety of string voltages. It needs to be small and versatile, to fit easily into the space constraints of the cluster, and produce little EMI, to minimize R&D efforts and eliminate the need for costly metal-shielded EMI cases. It should also be efficient. The Power by Linear LT8391A 2MHz buck-boost controller is unique in satisfying all of these requirements, making it possible to drive the entire headlight cluster, and more, with a single controller.

LT8391A 2MHz Synchronous Controller with Low EMI

The LT8391A is the first-of-its-kind 2MHz buck-boost controller for LED current regulation. The very high 2MHz switching speed enables the use of a single, small inductor and small overall solution size for high power LED applications. Unlike monolithic converters, whose power switches are contained within the IC package, controllers such as the LT8391A can drive external power switches with much higher peak currents, such as 10A. Such peak currents would burn up the small IC packages of typical integrated converters. In contrast, a controller with external 3mm × 3mm synchronous MOSFETs can deliver much higher power. These MOSFETs can be arranged in tight quarters with hot-loop capacitors for very low EMI. The unique peak switch current sense amplifier architecture places the sense resistor next to the power inductor, which is outside of the critical input and output hot loops—reducing EMI. Optional spread spectrum frequency modulation (SSFM) further reduces the controller’s EMI.

The 2MHz LT8391A 16V, 1.5A (24W) buck-boost LED driver in Figure 1 boasts as high as 93% efficiency with EMI filters and gate resistors as shown in Figure 2. Efficiency is 1%–2% higher with the optional EMI components removed. With small 3mm × 3mm MOSFETs and a single high power inductor, the temperature rise for this converter is low, even at 24W. At 12V input, no component rises more than 25ºC above room temperature. At 6V input, the hottest component rises less than 50ºC with a standard 4-layer PCB and no heat sink or airflow. It continues to run at full 24W load in the face of input transients down to 4.3V; or reduced load current via analog or PWM dimming when the input drops for long periods. The 8A–10A sense resistor makes this high power at low VIN possible.

Click image to enlarge

Figure 2. Efficiency of LED driver solution in Figure 1. Measurements made using 16V, 1.5A, demonstration circuit DC2575A LED driver with and without optional EMI components

The LT8391A includes the latest PWM dimming features and open LED fault protection. This synchronous buck-boost regulates current through a string of LEDs with a voltage that may or may not lie within the input voltage range, such as the 9V–16V car battery or a truck battery (18V–32V). It can run down to 4.0V cold crank input and can withstand up to 60V input transients. The LT8391A provides up to 2000:1 PWM dimming ratio at 120Hz and can use its internal PWM dimming generator for up to 128:1 accurate dimming ratio without the need for an externally supplied PWM clock.

CISPR 25 EMI for Automotive Applications

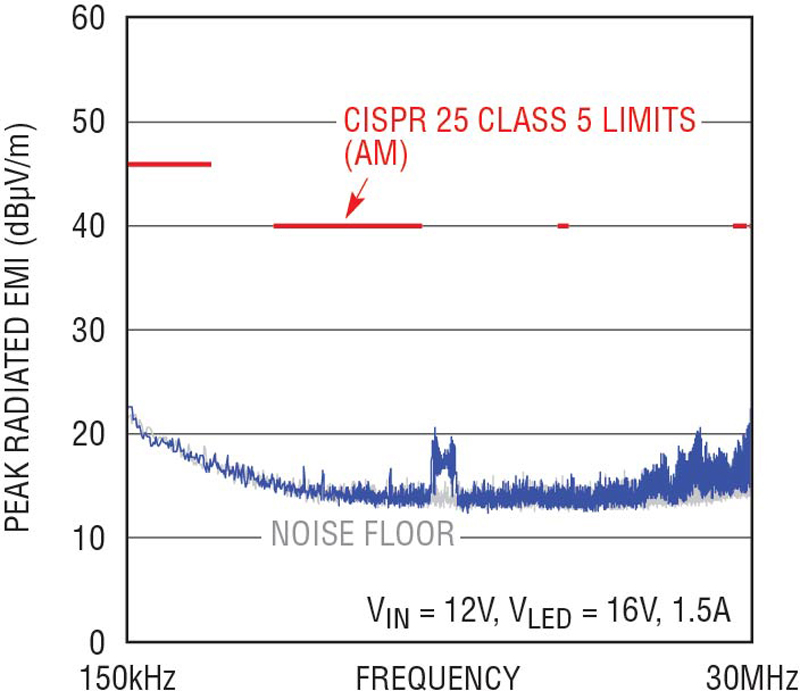

The 2MHz LT8391A LED driver in Figure 1 is designed for automotive headlights. It uses AEC-Q100 components and meets CISPR 25 Class 5 radiated EMI standards. Spread spectrum frequency modulation (SSFM) reduces EMI, and also runs flicker-free simultaneously with PWM dimming as shown in Figure 7. Its small size is highlighted by its small inductor and especially small input and output EMI filters. Large LC filters are not needed for 2MHz converters and only small ferrite beads are used for high frequency EMI reduction.

Automotive EMI requirements are not easily met by high power converters. High power switches and inductors, placed on large PCBs next to large capacitors can create undesirable hot loops, especially when a large sense resistor is included. The unique LT8391A buck-boost architecture removes the sense resistor from both the buck and boost switch-pair hot loops, enabling low EMI.

Figures 3 and 4 show measured EMI of the 24W LED driver of Figure 1. Despite this controller’s 2MHz operating frequency and 24W of power, this buck-boost passes CISPR 25 Class 5 radiated and conducted EMI. Class 5 is the most stringent requirement and the goal of most automotive EMI testing. Converters that cannot pass Class 5 EMI either get designed out of automotive circuits or must be encased in large metallic EMI shields. Even if the bulkiness of the shield does not create assembly issues, adding them is costly.

Click image to enlarge

Figure 3. LT8391A demonstration circuit DC2575A passes CISPR 25 Class 5 automotive radiated EMI

Click image to enlarge

Figure 4. LT8391A demonstration circuit DC2575A passes CISPR 25 Class 5 automotive conducted EMI

Buck-Boost for Multi-Beam Applications

LED headlight clusters can be both innovative and artistically creative. High beams and low beams can be wrapped up with nifty and distinctive daytime running lights (DRL). Because the daytime running lights are only needed when high and low beams are off, a single LED driver can be used to power either the high and low beam LEDs or the daytime running lights. This only works if the LED driver has a flexible input-to-output ratio and can both step-up and step-down the input-to-output voltage. A buck-boost design satisfies this requirement.

The multi-beam LT8391A buck-boost LED driver in Figure 5 can drive LED string voltages ranging from 3V to 34V. This enables it to drive both a low beam string and create a high beam by adding LEDs to the low beam string. The same driver switches over and drives a higher voltage, yet lower current, DRL. Switching from low-beam-only LEDs to a low/high beam combo string generates no spike on the output voltage or LED current as shown in Figure 6a. The LT8391A can transition between boost, 4-switch buck-boost, and buck regions of operation smoothly. Changing from a small number of LEDs to a high number of LEDs without an LED spike can be challenging for a converter, but this multi-beam circuit does this with ease. Switching back from high and low beams to just low beams is also very clean, without any harmful LED spikes, as shown in Figure 6b.

Click image to enlarge

Figure 5. LT8391A multi-beam LED headlight cluster solution for low, high, and DRL lights

The same is true when switching to and from the DRL string. Figure 6c demonstrates how the low beam is turned off and the DRL is smoothly connected to the output capacitor. Even the LED current is changed from 1A (high and low beams) to 700mA (8 LEDs DRL) without any issues. Other trim or signal LEDs can be added in as well, and the DRL can be blinked as a signal light. Figure 6d shows how the DRL can be PWM dimmed with the internally set PWM generator and then switched over smoothly to low beams when darkness falls.

Automotive environments require robust solutions in the face of short-circuits and open LEDs. Short- and open-circuit conditions are safely handled by the multi-beam solution shown in Figure 6, and reported via the converter’s fault flag.

Click image to enlarge

Figure 6. Waveforms show smooth switchover between high + low, low and DRL LED strings for the LT8391A multi-beam application in Figure 5

FE and QFN Packages Fit Tight Spots

The LT8391A is available in a 4mm × 5mm 28-lead QFN for small size and a 28-lead TSSOP FE package for automotive designs. Both packages have thermally enhanced GND pads for power dissipation of the internal INTVCC LDO from higher voltages.

The internal LDO INTVCC regulator of these converters can handle driving four synchronous MOSFETs at 2MHz with about 15nC gate charge. The small size of the LT8391A FE 2MHz 16V, 1.5A demonstration circuit (DC2575A, based on the design of Figure 1) is shown in Figure 7. Only a single 5mm × 5mm inductor is necessary for this high power, versatile application.

Click image to enlarge

Figure 7. Compact solution: 2MHz demonstration circuit DC2575A, featuring LT8391A, drives 16V LEDs at 1.5A

Click image to enlarge

Figure 8. PWM dimming using internal and external PWM options; 1% and 0.05%, respectively

Conclusion

The LT8391A 2MHz, 60V buck-boost LED driver controller powers LED strings in automotive headlights. Its features include its low EMI 4-switch architecture and spread spectrum frequency modulation for meeting CISPR 25 Class 5 EMI requirements. The unique, high switching frequency allows it to operate above the AM band, requiring very little EMI filtering. Its small size and versatility enable use in headlight cluster LED strings of a variety of voltages and currents.

Table 1. High power, high efficiency synchronous buck-boost controllers for automotive power solutions

Click image to enlarge

Analog Devices