Author:

Andy Phillips, North America Sales Manager TDK-Micronas

Date

07/22/2019

It is hard to imagine a world without today’s modern networking and communications. Electronics either enables or powers just about everything in today’s digital world, including automobiles. The automotive electronics market will grow to reach over USD 350 billion by 2024 for passenger cars. Today, most new vehicles have more than 1,000 microcontrollers and other semiconductor components. Typically, the software used in these vehicles requires more than 10 gigabytes of storage space. Truly the driving experience has shifted significantly to provide younger drivers a better user experience that is more connected than ever before.

These younger drivers want to take their connected experience everywhere they go – not just at home or with their mobile devices – but also in their cars. And, while a more connected experience is demanded by this younger generation, there is also an increased desire by them to have less environmental impact than ever before. Unsurprisingly, older drivers are demanding better fuel efficiency and less environmental impact this as well, but these drivers often have greater buying power, and their automotive purchases ensure that these demands appear in newer cars. As a result, mobile behaviors will evolve in the future, and will not only affect the fuel efficiency and CO2 reduction of motor vehicles, but also lead to new technologies that are based on smart, flexible and diagnostic-capable semiconductor solutions.

More efficiency through standards

Various automotive industry working groups are putting standards in place that are focused on networking and electromagnetic compatibility (EMC) and other electronic applications, including embedded motor control. In the field of vehicle electrical systems, communication standards are associated with the transition from brush-type DC motors (BDC) to brushless DC motors (BLDC). This transition requires increased flexibility as well as enhanced performance in motor control. This is because BLDC motors provide highly-efficient control software for much greater efficiency and longer life compared to traditional BDC motors.

Combined with networking and diagnostic tools, this helps the automobile function as a single unit that can balance its current state with the outside world. Reducing the size of the semiconductor technology nodes to a single device - combined with the integration of analog, digital, memory and power components - is crucial to provide more functionality and less power consumption in ever smaller space. By utilizing the performance and flexibility of a marketable standard processor (CPU), the implementation of a smart actuator can be achieved, resulting in improved integration and a reduction of the total system costs. And, due to this increased flexibility and the reusability of hardware and software derivatives an ROI can be achieved in little time and minimal cost.

Integrated Circuit Flexibility and Standards

A motor control integrated circuit (IC) is an integrated microcomputer system that has all the necessary functions for the direct control of electronically commutated motors (EC motors), such as BLDC and stepper motors. The architecture of such a system must balance the hardware and software-based features. Definable algorithms allow for adaptation to various drive applications and enable cross-platform software development with different types of actuators. The result is lower cost and great efficiency as engineers can reuse hardware and software components. In addition, deeper integration into other systems and fewer components ensures less system failures over time.

Embedded drives include both electronic systems and mechanical systems, including the motor. A robust direct power supply is required to limit disturbances on communication lines while supplying power for the entire vehicle's electrical system.

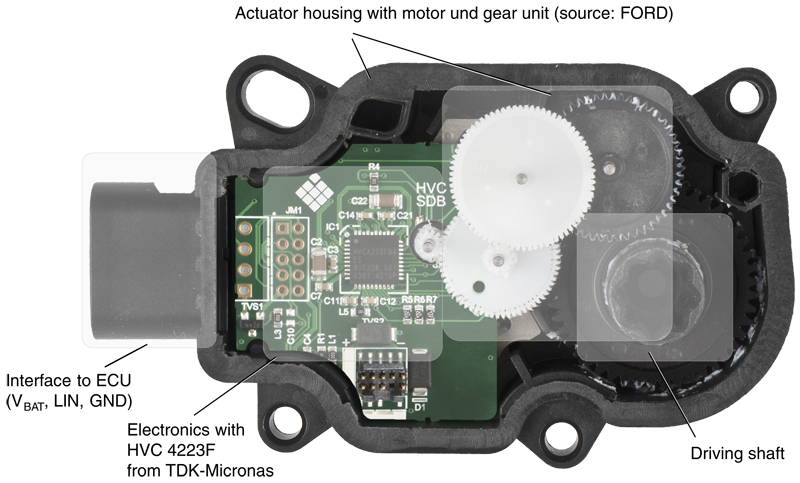

The motor should be controlled by a single-chip solution, such as the HVC 4223F from TDK-Micronas, which can provide the optimal balance between real-time requirements and programmability, while limiting system cost. A common commutation scheme in such BLDC motor systems is a sensorless six-step commutation with speed and current control. The calibration of the actuator can optionally be performed without absolute position sensor by driving into the end stop. The computational performance should minimize mechanical stress on the engine and transmission. In systems with higher redundancy requirements, a Hall switch can also be used to record the absolute position. And, the IC should operate in a temperature range of -40°C to at least +125°C.

Click image to enlarge

Figure 2: Block diagram of the HVC 4223F from TDK-Micronas

In the development and qualification of automotive ICs, a large number of standards must be observed. The input voltage regulators must comply with on-board electrical system standards (such as ISO Pulse). Emission limits must be adhered to. EMC and ESD quality standards must be met. For automotive qualification, the IC must undergo the various tests of the AECQ100 standard. If the chip communication interface is connected to a higher-level ECU in the vehicle electrical system (for example via the LIN bus), appropriate conformance tests must be performed for physical layer and protocol layer of the bus interface.

Software and Storage

An increasing number of embedded drive systems are already using real-time operating systems (RTOS) with a compiled kernel size of less than 5kb. This should provide a static software architecture with function-queue scheduling with a CPU utilization in the range of 50 to 70 percent. It is important that the architecture have a defined Application Programming Interface (API) and corresponding hardware abstraction layer (HAL) libraries to ensure it is modular. The implementation of test interfaces in the HAL allows evaluation and quality assurance according to domain-specific models like the Automotive SPICE standard.

Diagnostic requirements such as ODB-II can also influence both memory size and software partitioning. Motor control, LIN communication (LIN stack) and boot code other factors that can increase the size of software packages. In addition, automotive storage systems require a storage overhead of 20 to 30 percent for extensions and updates to existing software.

Cost efficiency through integrated solutions

In automotive design, cost issue is always an issue. The development actuators, the mechanics, electronics, software and production properties are evaluated.

Depending on the selected drive and its reusability or scalability, motor control places a special emphasis on the flexibility and performance of the electronics and semiconductors. A fully integrated solution already has an internal microcontroller, communication interfaces, power supply, bridge drivers and transistors (MOSFET). Any additional costs of an multi-use programmable or integrated component is offset by the need for fewer total components in the design. The more that can be integrated into fewer components, the better – and lower the costs.

Click image to enlarge

Figure 3: Example of an embedded drive

An integrated solution can also result in less power consumption in the design. For example, in a discrete circuit design, the power supply may provide more or less power than is needed at any given time, however in a fully-integrated device the power supply can be optimized for the design. Through the use of a standard microcontroller, not only technical advantages but also costs can be reduced. Recurring tasks can be performed by different applications and software including the initialization routines of the device as well as basic algorithms for motor control.

Further cost savings can be achieved through built-in diagnostics. Real-time system status software helps provide better diagnostics and increased optimization resulting in a longer overall lifetime reliability of the entire system. Any changes can be precisely determined and optimized the system or updated by firmware.

Conclusion

A fully integrated solution for smart actuators results in new efficiency, flexibility and better integration, with fewer components and lower costs. In addition, a fully integrated solution offers tremendous advantages over a discrete design. Development is focused on just one building block, supported by the reduced number of external discrete components. The software and firmware provides a complete solution and is reusable within the system, provides better reliability and easier to certify.

The lower energy consumption and lower heat generation of the smart actuators benefits the lifetime of the application. Together with the extended diagnostic capability, the actuator is improved overall in terms of cost, function and life.

TDK-Micronas

www.micronas.com