Author:

Gabriela Born, Product Marketing Manager, XMC4000 Family, Infineon Technologies

Date

03/05/2012

Infineon has taken their wealth of know-how in microcontroller design for real-time critical control applications to combine it with all benefits of an industry standard core. The unique result, the 32-bit XMC4000 microcontroller family based on ARM® Cortex™-M4, is dedicated to industrial applications. XMC stands for a family of "Cross-market Microcontrollers". Target segments include energy-efficient drives, renewable energy, factory and building automation. This article elaborates on the motivation for Infineon's architecture decision, the portfolio and the key innovations of this family.? Striving for energy-efficient solutions the XMC4000 devices greatly benefit from Infineon's well-known set of configurable peripherals, fast embedded Flash technology, high quality standards, long product life times, and the ability to support high temperature requirements of up to 125 °C, backed by the company's background as a leading supplier to automotive markets. Adding the next-generation of DAVE™ - DAVE™ 3 -, a revolutionary approach to lower software efforts, industrial system developers can count on a powerful microcontroller platform for their numerous industrial applications. With the new XMC4000 (Figure 1) family - starting with the XMC4500 series - Infineon addresses three high-level trends for microcontrollers in industrial drives, automation and renewable energy systems: the need to enable higher energy efficiency of the systems, the need to enhance connectivity between systems and the challenge to reduce software complexity which seems to explode in many of today's projects.

Higher energy efficiency On one hand there is an increasing effort to supply energy from renewable energy systems. One the other hand the best way to cut down CO2 emissions is to reduce overall power consumption, and electric motors play a key role in power consumption. According to a study by VDE electrical drives used in industry and households alone account for 50% of the total electrical energy consumed. According to VDE, more efficient three-phase motors in the power range from 1.1 to 37 kW offer the greatest potential for saving electrical energy. There are several ways the microcontroller can contribute to this improvement: higher computing performance to allow faster control loops and more advanced algorithms, optimized peripherals to enable faster and more accurate measurement of analog signals and a faster and more adapted PWM generation. The new XMC4000 family of 32-bit microcontrollers provides all the named features and enables very energy efficient designs. Enhanced connectivity Enhancing connectivity in industrial systems is another key trend. This trend takes two directions: Connectivity within the real-time critical domain and connectivity to the "outside" world. Within the real-time critical domain simple standards like UART, SPI, IO-Link or proprietary protocols are wide-spread, cost efficient and reliable. For higher band-width requirements real-time Ethernet might be a future trend, but currently suffers due to the fact that there are too many flavors and there is no unique standard established. For connectivity to the outside world there are two main use cases: For manual code update or download a high-speed interface like USB or an SD/MMC interface for data card access are required. For remote process management, monitoring or maintenance Ethernet is evolving as the main standard Reduced software complexity Both of the previous trends drive up the requirements for software. Several industry studies confirm software complexity is one of the major problems for embedded system development. This is true especially for small and medium sized companies with comparably small development teams of some ten engineers. Especially communications stacks, operating system integration and re-use of optimized algorithms are key challenges. High-performance core Infineon selected for its XMC4000 portfolio the ARM Cortex-M4 processor core. The main reason to choose the M4 core instead of the M3 is the availability of DSP instruction support and a floating point unit. Overall this allowed Infineon to roughly double the computing performance compared to its 16-Bit C166 based microcontroller families, which were recognized as leading in real-time performance since their introduction in the early 1990ties. For even higher real-time performance Infineon continuously invests in its TriCore based product families. A significant advantage of the XMC4000 family is the availability of a broad ecosystem and 3rd party software for the ARM Cortex M architecture as a commonly used standard core.

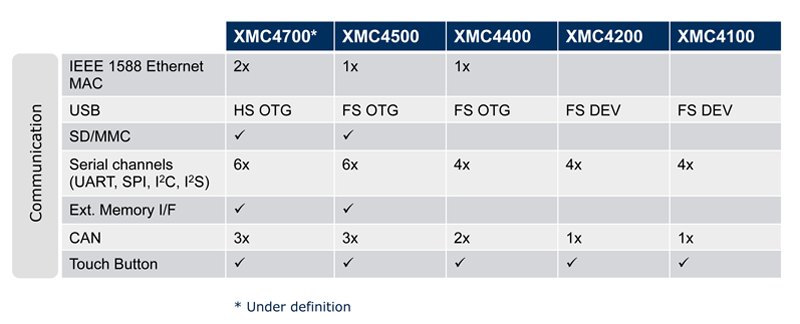

Five series with scalable features The XMC4000 portfolio consists of five series: XMC4100, XMC4200, XMC4400, XMC4500, and XMC4700 (Figure 2a).These series scale in terms of frequency, memory, number of IOs and type and availability of peripherals (Figure 2b). The basic architecture with a high-performance flash, which is also used in Infineon's automotive qualified TriCore microcontrollers, the high-speed bus-matrix and the 2 peripheral busses, is identical for all family members (Figure 3). All peripherals were optimized for high-level software programming. They are built on flexible hardware blocks which can be configured by software to meet the exact application need. Thus the whole XMC4000 portfolio was defined to be scalable and compatible to allow easy migration from one series to another. The integrated resolver exciter and sigma-delta demodulator are examples of unique features that reduce BOM, system cost and system complexity.

Energy saving peripherals XMC4000 comes with several innovative peripherals (Figure 4) like a completely new developed timer unit for PWM generation, allowing efficient control of all motor and inverter types. With this peripheral Infineon levers its vast know-how and experience in timer design: the CCU6 which Infineon introduced roughly 10 years ago for its 16 Bit portfolio is still recognized as leading for electric motor control. The GPTA unit in the TriCore portfolio is regarded as best in class for engine control. Based on this experience Infineon now developed enhanced timer modules for industrial applications. Key advantages of the new CCU4 and CCU8 timer modules are: They consist of several, identical "capture/compare slices" which can be e.g. easily concatenated. Their register sets and hardware symmetry make it easy to map high-level data structures to the hardware or re-locate code from one unit to another one. Identical, repetitive HW structures allow for SW re-use between the timer slices. Other feature enhancements include a dithering PWM for higher resolution and improved electromagnetic emissions, a floating pre-scaler, asymmetrical PWM generation, asymmetrical dead-time generation for rising and falling edge etc. The XMC4400, XMC4200 series will contain a high resolution PWM unit with a resolution of 150ps. This is a dedicated peripheral for highest energy efficiency in power conversion as needed in power supplies or solar inverters. Up to two positioning interface modules are available to support quadrature encoders, hall sensors or multi-channel positioning information. The unit provides input filtering, edge detection and provides control signals for the PWM unit. The XMC4000 family comes with up to four parallel 12-Bit ADCs with a sampling time of 70ns and a conversion time of 500ns. Overall those four ADC modules provide 26 high-speed ADC channels. With an oversampling algorithm the resolution can be increased to 14 Bit. The ADCs are optimized to provide a wide range of autonomous operation modes which either allow to save on external components or reduce processor loads. Examples for this include a fast comparator mode, zero crossing detection, conversion of multiple signals in a programmable sequence, signal plausibility checks, arbitration in case of injection conversions, result data processing (IIR/FIR filtering) etc. In case a high-precision or a galvanic isolated ADC measurement is required XMC4000 offers up to four Delta-Sigma interfaces to demodulate and filter up to four data streams. With this optimized ADC functionality the XMC4000 covers a wide range of application use case for inverter control in electrical motors or renewable energy applications.

Optimized for inverter control XMC4000 is optimized for inverter control in electric drives and renewable energy systems (Figure 5). Efficiency improvements of inverters require simultaneous measurement of three phase currents and additionally simultaneous measurements of input currents or other environmental parameters. XMC4000 addresses this with up to four parallel 12-bit ADCs. With 3.5 million samples per second the ADCs are not only very fast; they can also post-process the data with digital filters, for example to implement an oversampling algorithm in hardware. On the one hand this offloads the processor, on the other hand it improves real-time performance as the peripherals can act without any software overhead. Galvanic isolated current measurements are supported by an integrated delta-sigma demodulator: This concept reduces system cost when working with an external, isolated delta-sigma ADC, as opposed to current designs it eliminates the need for an additional interface IC. Besides the fast 12-bit ADCs the new XMC4000 family provides the most advanced PWM units and timers for efficient drives. One of the key strengths of all Infineon microcontroller families is the tight coupling between the PWM generation units and the ADCs. Especially for electric motor control this is a key functionality as it significantly reduces the interrupt load for the processor and enhances the reaction time. In the XMC4000 family those capabilities are even enhanced: Instead of fixed hardware connections it provides a connection matrix which allows FPGA-like connections between different output and input trigger signals of hardware modules.

Well connected As connectivity is a major trend the XMC4000 family supports a wide range of communication standards (Figure 6): Connectivity to the administration and maintenance layer is established via USB OTG, Ethernet and SD/MMC peripherals. USB comes in different flavors depending on the series: high-speed/full-speed, host/device. Ethernet contains the IEEE 1588 time-stamping functionality which allows real-time Ethernet software implementation. Furthermore connectivity within the embedded system can be established with up to 3 MultiCAN nodes and up to 6 universal serial interface channels. Both hardware modules are highly flexible and offload the CPU significantly through pre-filtering of messages or message buffering. The universal serial interface channels can be freely defined by software to implement one of the following standards: UART, SPI, Quad-SPI, IIC, IIS, LIN. This increases the flexibility for the software and hardware designer significantly and allows long-term scalable platform solutions. For external memories and memory-mapped IO devices XMC4000 offers a high-speed parallel external bus interface. Complete tool chain In addition to a number of commercial 3rd party development tools Infineon offers DAVE 3, a free, Eclipse-based software framework. This new DAVE includes a free tool-chain and an extendable autocode generator, facilitating the use of pre-defined SW components that can be graphically selected and combined. In contrast to the state of the art approach with libraries and code examples, this new approach allows higher software abstraction, easier integration and maintenance. It is an open platform allowing easy extensions and adaptations, like e.g. the addition of applications through 3rd parties based on a SDK. The DAVE store hooks the user up with an ever growing developer community: Tested low level drivers, RTOS, software stacks and higher-level applications can be downloaded and shared. While the main focus is on free software components DAVE 3 is also ready to integrate commercial 3rd party software components. In addition to the free compiler, linker, debugger and flash loader, there are plug-ins from commercial tool-vendors available. This allows the user to fully benefit from this concept: staying with their preferred IDE while fully utilizing the autocode generation functionality of DAVE 3. Availability Samples of the XMC4500 lead series are available since August 2011. After extensive testing customer sampling will start in March 2012. Infineon's DAVE™3, a wide variety of 3rd party tools and evaluation kits will be available at the same time. Volume production starts in Q2 2012. The XMC4400, XMC4200, XMC4100 series will be in production in Q1 2013, samples will be available in Q4 2012. DAVE can be downloaded at www.infineon.com/dave www.infineon.com/xmc