Author:

Radovan Faltus, Technical Marketing, AVX Tantalum

Date

08/13/2012

DCL (direct current leakage) is an effect common to all capacitors. DCL values and behavior under varying electrical and environmental conditions relate to the capacitor's dielectric. The leakage current in tantalum and niobium oxide capacitors consists of the dielectric absorption current and the fault current that results from impurities and irregularities within the dielectric. Since operating currents in most systems are significantly higher than a capacitor's leakage current, a circuit's functionality remains unaffected by DCL. However, in a battery-operated application the leakage of the capacitor will directly influence standby time, as it directly discharges energy from the battery. This occurs frequently in applications like mobile phones, MP3/MP4 players, DVD players, and in automotive applications where battery-operated wireless sensor transmitters, for example, use capacitors. Battery-powered, handheld equipment commonly use capacitors with 3.7V lithium-ion rechargeable batteries for several functions.

where C is the nominal capacitance, VR is the capacitor's rated voltage, and k is a dielectric-dependent constant. For example, values of k corresponding to three of AVX's capacitor series are:

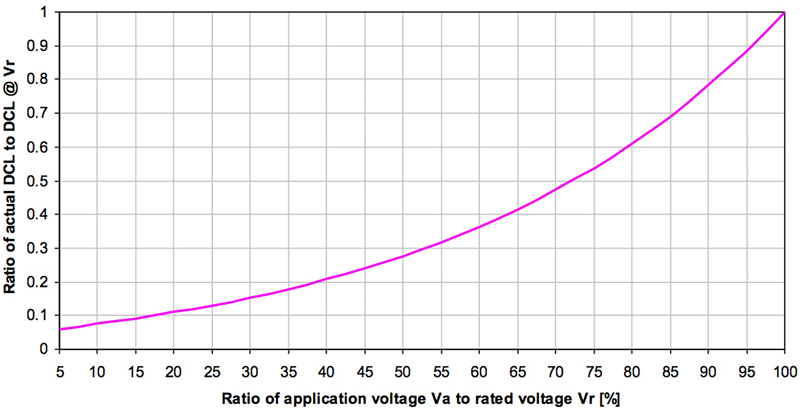

Optimal voltage derating for minimal DCL To achieve the optimal leakage current ratings for the application (DCLA) at room ambient temperature, we need to consider two factors: the basic DCL defined at rated voltage (Vr as in Eq 1); and the DCL ratio versus voltage derating, as shown in Figure 2:

where RI is the ratio of DCLA:DCL at VR k are the dielectric-dependent constants given with Eq 1.

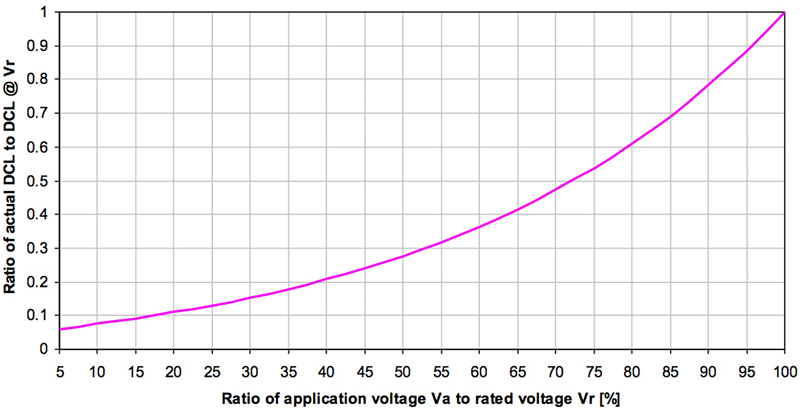

Figure 3 shows The maximum DCL multiplier versus VA/VR for a fixed application voltage VA. The maximum DCL value varies with capacitor type, nominal capacitance, and rated voltage. The shape of the graph will be the same, so you can identify the range of Va/Vr (derating) values with minimum DCL as the �optimal' range. Therefore, you'll obtain the minimum DCL when a capacitor is operates at 25 to 40% of its rated voltage, which translates to a rated capacitor voltage 2.5 to 4 times higher than the application's operating voltage. Comparison in typical battery circuits The typical energy source of a handheld device is a lithium-ion rechargeable battery with a nominal voltage VA = 3.7V. To support device functionality, designers can choose from several different capacitor series.. Where the VA is 3.7V, the optimal rated voltage, VR, is 10V, (which means optimal operating conditions are at 37% of rated voltage. This ratio of VR:VA is independent of capacitance. www.avx.com