Author:

By Christopher R. Swartz, Principal Applications Engineer, Picor Corporation

Date

11/17/2010

System designers have struggled to determine the type of distributed power system to best meet the needs of the system while still retaining high efficiency, reliability, low cost and most of all, flexibility to adapt to the fast changing requirements, its size and power density make it an ideal solution for the challenging requirements of end-systems such as advanced telecom and wireless infrastructure, networking & communications, Power-over-Ethernet applications and high speed server platforms. Distributed Power Architecture (DPA), for example, supplies each output load voltage by an isolated DC-DC converter appropriately sized for the load current required. This method usually produces the higher overall efficiency ? in comparison with Intermediate Bus Architecture (IBA) ? due to the lower number of "serial" conversion stages and lower distribution losses of the input bus, but it usually results in higher cost and larger board area requirement. IBA usually reduces the board area and cost in comparison to DPA. An isolated bus converter (IBC) decreases the high voltage down to a level that is the aggregate average sweet spot for the narrow range non isolated point-of-load converters (NiPOL) in terms of duty cycle and efficiency. Each NiPOL then operates off of this bus voltage and produces a regulated output voltage for each load. A new high-density isolated DC-DC converter combines the advantages of both DPA and IBA topologies by delivering 60W of isolated output power in half the size of existing solutions, setting a new standard for power density by delivering over 400W/in3. It combines isolation, voltage transformation, and output regulation into a high density, surface-mount Power-System-in-Package (PSiP) platform with a tiny footprint (0.57 in2) and very low profile (0.26 inch), making it ideal for applications where board space, airflow, and height dimensions are critical. The new converter operates over a wide input voltage range of 36Vdc to 75Vdc while providing a regulated 3.3V output at up to 18A output current. It can withstand input voltage transients of up to 100V for 100ms and provides 2250V input-to-output isolation. Looking more like an integrated circuit than a power supply, the converter, designated PI3101, owes its existence to a number of innovative technical concepts. Firstly, its patented Double-Clamped Zero-Voltage Switched (DCZVS) buck-boost topology. State-of-the-art planar magnetics are employed, which allow for extremely low leakage inductance and superior power transfer from primary to secondary. Further, proprietary control with advanced silicon integration, in conjunction with proprietary gate drive techniques, allow for precise timing and management of the high-performance power conversion stage. Together with the magnetic design, the control circuitry makes switching frequency operation in excess of 1MHz a reality. The high-density, surface-mount PSiP packaging facilitates PCB layout optimization for high switching frequency, offers the designer the opportunity to employ a variety of cooling techniques, and protects the circuit components against mechanical and ambient factors, thus improving reliability. Proprietary sampled feedback control eliminates optical isolation and external feedback-loop compensation requirements. Finally, proprietary, high performance MOSFET technology with best-in-class figure of merit attributes, contributes to high efficiency. The PI3101 contains all of the necessary circuitry for a completely isolated and regulated power supply. It can be trimmed +/-10% using a simple resistor connecting the TRIM/SS pin either to the ENABLE pin, for trimming higher, or to the input -IN pin for trimming lower. For modified start up, a soft-start capacitor can be added externally. The PI3101 can be turned off and on remotely by toggling the ENABLE pin. This pin also provides the user with a 5V reference. The PI3101 contains an accurate temperature monitor function, which outputs an analog voltage proportional to the internal temperature of the product on the TM pin. The TM pin also serves as a fault alarm flag indicating that there is a problem when asserted low. The PI3101 is well protected with an array of protection features. There are two current limits to protect against short circuit and overload, input over voltage and under voltage lockout with auto restart, output over voltage protection with automatic recovery and over temperature shutdown with automatic recovery. Figure 1 shows a typical complete power supply using the PI3101 with system fuse and optional input filter and soft start capacitor components. The heart of the PI3101 is a proprietary Double-Clamped Zero Voltage Switched power stage topology, enabling operating frequencies in excess of 1MHz. Figure 2 shows the topology diagram for the PI3101.

The PI3101 uses four primary MOSFETS and a synchronous MOSFET that together form the power delivery subsystem. Q1 and Q4 are power switches and Q2 and Q5 are clamp switches. Q3 is the synchronous MOSFET. It is useful to compare the figure of merit (FOM) of isolated power converters with respect to their relative size, power density and key performance metrics (see Table 1). Converter Y represents the best in class for the 1/16th brick form factor. Converter X represents about the mean level of performance of all converters reviewed. It is clear that the PI3101 can be competitive when matched against converters of twice the size. The full-load efficiency is equivalent to Converter X while delivering a very significant improvement in power density. The PI3101 has better than twice the power density of the highest power 1/16th brick and nearly 3.5 times the power density of the industry average for a regulated 1/16th brick.

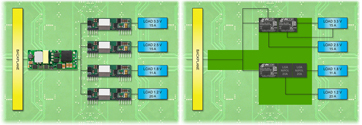

Consider the DPA configurations shown in Figure 3. The smallest isolated approach before the PI3101's existence would consist of four 1/16th bricks to produce the regulated output power. Using PI310x Cool-Power family the total system size can be reduced in half. Figure 3 shows a scaled version of the actual 1/16th bricks employed on the left comparing the resulting difference in size by using the PI310x Cool-Power based solution on the right.

Similarly, the IBA solutions are compared in Figure 4. The required output power of the loads is equal to roughly 130W. If the input bus is a wide range 36-75V and a fixed bus IBA is used, the isolated converter will need to be an 1/8th brick. Each output NiPOL would be a DOSA compatible DC-DC converter.

By combining IBA with DPA using PI310x's to power the 2.5V & 3.3V loads directly and another PI310x as an IBC feeding a couple of high density NiPOLs for the 1.8V and 1.2V rails mounted vertically, an even more dramatic size reduction can be realized. The high power density of the PI310X family allows system designers the flexibility to power the ever-shrinking technology of the future. www.picorpower.com