Author:

Reported by Cliff Keys, Editorial Director, PSD

Date

05/30/2011

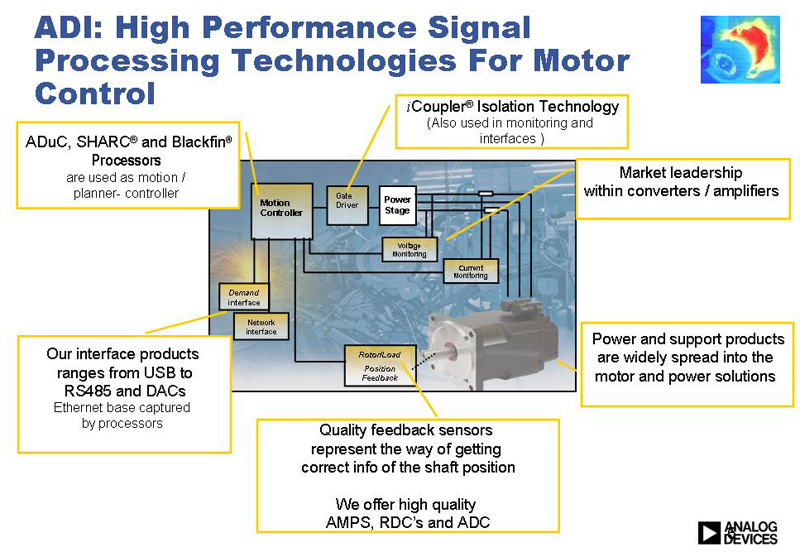

I was fortunate to meet with Anders Frederiksen, Segment Marketing Manager for ADI recently at the PCIM show in Nuremberg. ADI's demonstrations showed how to simplify feedback and sensing, isolation of control and interface, power management, communication and data processing for industrial motor and power control. Analog Devices, Inc. (ADI), a global leader in high-performance semiconductors for signal processing applications, demonstrated several development platforms targeting the design challenges engineers face in feedback and sensing, isolation of control and interface, power management, communication and data processing for permanent magnet, servo and other motor types. In addition, ADI presented four technical papers highlighting data converter, processor, isolation, interface and power management technologies. One of the papers, "Integration of Isolation for Grid-Tied Photovoltaic Inverters," written by ADI Fellow Baoxing Chen, was nominated for a "Best Paper" award at PCIM Asia.

Anders talked to me about the key trends in motor control which are developing in this huge market Efficiency - There are different standards depending on region, power level and system integrations (end solution). Motors are now changing from ACIM (induction) to PM (permanent magnet) Decentralized systems - Systems that interconnect over communications interfaces are now becoming prevalent and also systems that bundle the motor and the drive together in a single casing Ease of installation and use - Make the system easier to install and setup for new firmware or optimization Increased Software Functionality - Enhancing use of smart math to optimize the controller capability and the use of different levels of IP interface software / high level graphical tools to ease the setup of the drive and system Miniaturization - Makes installation so much easier and more focused on the performance within the actual system.

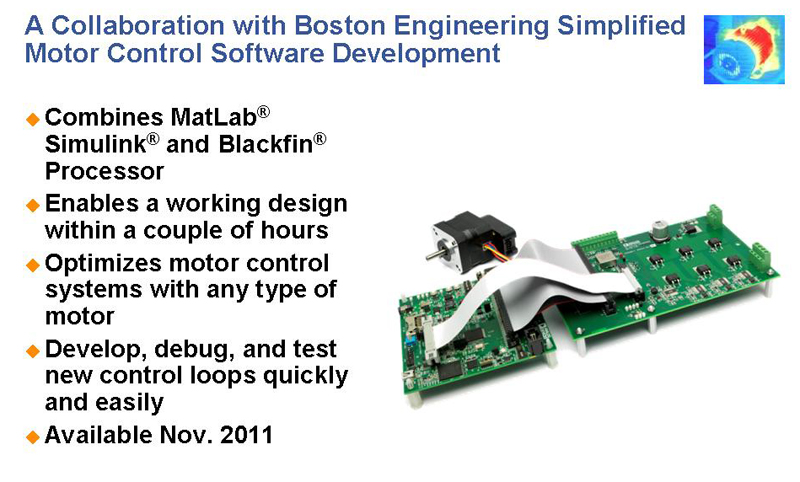

Live demonstrations included: Power Factor Correction Platform Demonstration This demonstration showed visitors how to simplify the adoption of intelligent power management systems using a flexible, digitally-controlled PFC (power factor correction) engine, accurate input metering and GUI interface. The demo included the industry's first digital power factor correction IC with accurate power metering capability. Using continuous-conduction mode PFC techniques, designers can optimize system harmonic performance and maximize efficiency across the load range. Motor Control Development Platform Demonstration This demonstration featured a high performance controller platform used to develop and optimize motor control systems for permanent magnet and other types of motors. Importantly, this demo featured a development tool chain aligned with Matlab/Simulink that incorporates a complete signal chain illustrating ADI's high precision data converters, processors, isolation circuits, and interface and power ICs. Servo and Communication Development Platform Demonstration This development platform demonstrated enhanced internal and external communication capabilities that include design scalability, flexibility, advanced algorithm development and ease of use for use with the growing need for sophisticated higher speed servo motors. The demo highlighted ADI's SHARC® processor and specialized communication modules. ADI also showed a robotic arm with full controller flexibility using a LabVIEW® tool. Isolated CAN Network Demonstration This demonstration showed the seamless integration of an isolated CAN transceiver over an isolated CAN network. The demo highlighted the application of ADI's evaluation tool kit to a robotic arm control.

Design support The increasing need for higher performance signal processing technologies for all motor types makes ADI a key partner to achieve the higher performance and efficiency needs of this industry. The company has the key ingredients for more efficient motor control systems with its advanced signal processing technologies. These ingredients not only help to differentiate designs in this highly competitive marked, but also with ADI's advanced design tools, can make the design phase easier and much faster, getting to market to hit the sweet spot in terms of the bottom line. To subscribe to Analog Dialogue, ADI's monthly technical journal, visit: www.analog.com/library/analogDialogue